User:Rhion/History of the slate industry in Wales

The history of the slate industry in Wales goes back to Roman times, with slate being used to roof the fort at Segontium (modern Caernarfon). The most important slate producing areas were in north-west Wales, notably the Penrhyn Quarry near Bethesda, the Dinorwig Quarry near Llanberis, the Nantlle Valley quarries and Blaenau Ffestiniog, where the slate was mined rather than quarried. Penrhyn and Dinorwig were the two largest slate quarries in the world. and the Oakley mine at Blaenau Ffestiniog was the largest slate mine in the world.[1]

Beginnings

[edit]

The slate deposits of Wales belong to three geological series, Cambrian, Ordovician and Silurian. The Cambrian deposits run south-west from Conwy to Pwllheli; these deposits were quarried in the Penrhyn and Dinorwig quarries and in the Nantlle valley. There are smaller outcrops elsewhere, for example on Anglesey. The Ordovician deposits run south-west from Bettws-y-Coed to Porthmadog; these were the deposits mined at Blaenau Ffestiniog. There was another band of Ordovician slate further south, running from Llangynnog to Aberdyfi, quarried mainly in the Corris area, with a few outcrops in south-west Wales, notably Pembrokeshire. The Silurian deposits are mainly further east in the Dee valley and around Machynlleth.[2]

While the virtues of slate as a building and roofing material were recognized from the Roman period, transport problems meant that it was usually used fairly close to the quarries. There was some transport by sea. A poem by the 15th century poet Guto'r Glyn asks the Dean of Bangor to send him a shipload of slates from Aberogwen, near Bangor, to Rhuddlan, to be used to roof a house at Henllan, near Denbigh.[3] The wreck of a wooden ship carrying finished slates was discovered in the Menai Strait and is thought to date from the 16th century.

Small scale quarrying of slate was carried on in several areas. The Cilgwyn quarry in the Nantlle valley dates from the 12th century, and is thought to be the oldest in Wales.[4] The first record of slate quarrying in the neighbourhood of the later Penrhyn Quarry was in 1413, when a rent-roll of Gwilym ap Griffith records that several of his tenants were paid 10p each for working 5,000 slates.[5] Aberllefenni Slate Quarry may have started operating as a slate mine as early as the 14th century. The earliest confirmed date of operating is 1500 when the local house Plas Aberllefenni was roofed in slates from the mine. By the second half of the 16th century there was a small export trade of slates to Ireland from ports such as Beaumaris and Caernarfon.[6]

Growth (1760-1830)

[edit]

Until the late 18th century slate was extracted from many small pits by small partnerships of local men, who did not own the capital to expand further. The quarryment usually had to pay a rent or royalty to the landlord, though the quarrymen at Cilgwyn did not. In the 1760s Methusalem Jones, previously a quarryman at Cilgwyn, began to work the Diffwys quarry at Blaenau Ffestiniog, which became the first large quarry in the area.[7] The large landowners were initially content to issue "Take Notes", allowing individuals to quarry slates on their lands for a yearly rent of a few shillings and a royalty on the slates produced.[8] The first landowner to take over the working of slates on his land was the owner of the Penrhyn estate,Richard Pennant, later Baron Penrhyn. In 1782 the men working quarries on the estate were bought out or ejected and Pennant appointed James Greenfield as agent. By 1792 the Penrhyn Quarry was employing 500 men and producing 15,000 tons of slate per year.[9] At Dinorwig a single large partnership took over in 1787, and in 1809 the landowner,Thomas Assheton Smith of Vaynol, took over the management of the quarry. The Cilgwyn quarries were taken over by a company in 1800, and at all three locations the scattered workings were amalgamated into a single quarry.[10]

Slates from Penrhyn Quarry were transported to the sea at Port Penrhyn on the narrow gauge Penrhyn Quarry Railway built in 1798, one of the earliest railway lines. The Padarn Railway, opened in 1824 as a tramway for the Dinorwic Quarry, and converted to a railway in 1843, ran from Gilfach Ddu near Llanberis to Port Dinorwic.

Peak production (1831-1885)

[edit]

In 1831 slate duty was abolished, and this helped to produce a rapid expansion in the industry, particularly since the duty on tiles was not abolished until 1833.[11]

The Ffestiniog railway line was constructed between 1833 and 1836 to transport slate from the quarries around Blaenau Ffestiniog to the coastal town of Porthmadog, where it was loaded onto ships. The railway was graded so that loaded slate waggons could be run by gravity downhill all the way from Blaenau Ffestiniog to the port. The empty waggons were hauled back up by horses, which travelled down in special 'dandy' waggons. This helped expansion at the Blaenau Ffestiniog quarries, which had previously had to cart the slate to Maentwrog where it was loaded onto small boats to be taken down the River Dwyryd to the estuary, where it was transferred to larger vessels. In 1843 the Padarn Railway become the first to use steam locomotives. The Ffestiniog Railway converted to steam in 1863, and the Talyllyn Railway was opened in 1866 to serve the Bryn Eglwys quarry above the village of Abergynolwyn.[12] The Corris Railway had opened as the horse-worked Corris, Machynlleth & River Dovey Tramroad in 1859, connecting the slate quarries around Corris and Aberllefenni with wharves on the estuary of the Afon Dyfi.

From 1860 onwards slate prices rose steadily. Quarries expanded and the population of the quarrying districts increased, for example the population of Ffestiniog parish increased from 732 in 1801 to 11,274 in 1881.[13]Total Welsh production reached 350,000 tons a year by the end of the 1860s. Of this total, over 100,000 tons came from the Bethesda area, mainly from the Penrhyn Quarry. Blaenau Ffestiniog produced almost as much, while the Dinorwig Quarry alone produced 80,000 per year. The Nantlle Valley quarries produced 40,000 tons, while the remainder of Wales outside these areas produced only about 20,000 tons per year.[14] By the late 1870s Wales was producing 450,000 tons of slate per year, compared with just over 50,000 tons for the rest of the United Kingdom, which then included Ireland.[15] By 1882, 92% of Britain's production was from Wales with the quarries at Penrhyn and Dinorwig producing half of this between them.

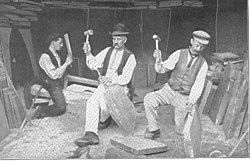

The men worked the slate in partnerships of four, six or eight and these were known as "Bargain Gangs". "Bargains" were let by the "Bargain Letter" when a price for a certain area of rock was agreed. Adjustments were made according to the quality of the slate and the proportion of 'bad' rock. The first Monday of every month was "Bargain Letting Day" when these agreements were made between men and management. Half the partners worked the quarry face and the others were in the dressing sheds producing the finished slates. Rubblers helped to keep the chambers free from waste: one ton of saleable slate could procuce up to 30 tons of waste. The men had to pay for their ropes and chains, for tools and for services such as sharpening and repairing. Subs (advances) were paid every week, everything being settled up on the "Day of the Big Pay". If conditions had not been good, the men could end up owing the management money. This system was not finally abolished until after the Second World War.

Because of this arrangement, the men tended to see themselves as independent contractors rather than employees on a wage, and unions were slow to develop. There were grievances however, including unfairness in setting bargains and disputes over days off. The North Wales Quarrymen's Union (NWQMU) was formed in 1874, and the same year there were disputes at Dinorwig and then at Penrhyn. One of the founders of the union, Morgan Richards, described in 1876 the conditions when he started work in the quarries forty years before:

- I well remember the time when I was myself a child of bondage; when my father and neighbours, as well as myself, had to rise early, to walk five miles before six in the morning, and the same distance home after six in the evening; to work hard from six to six; to dine on cold coffee, or a cup of buttermilk, and a slice of bread and butter; and to support (as some of them had to do) a family of perhaps five, eight or ten children on wages averaging from 12s to 16s a week.[16]

Industrial unrest and decline (1885-1938)

[edit]

At the Penrhyn quarry, George Sholto Gordon Douglas-Pennant took over from his father Edward Gordon Douglas-Pennant in 1885, and in 1886 appointed E.A. Young as chief manager.[17] A more stringent management regime was introducted, and relations with the workforce deteriorated. Industrial relations were worsened by differences in language, religion and politics between the two sides. The owners and top managers were English-speaking, Anglican and Tory, while the quarrymen were Welsh-speaking and mainly Nonconformist and Liberal. Negotiations between the two sides usually involved the use of interpreters. The first of two prolonged strikes by workers demanding better pay and safer conditions lasted eleven months in 1896.

A second lock-out or strike[18] at the Penrhyn Quarry began on 22 November 1900 and lasted for three years. There was great deal of hardship among the 3,000 workers, as the union's funds for strike pay were inadequate. When Lord Penrhyn re-opened the quarry, about 400 men returned to work, to be castigated as "traitors" by the remainder. Eventually the workers were forced to return to work on terms laid down by Lord Penrhyn. Many of the men considered to have been prominent in the union were not re-employed, and many of those who had left the area to seek work elsewhere did not return. The dispute left a lasting legacy of bitterness in the Bethesda area.

The loss of production at Penrhyn led to a temporary shortage of slates and kept prices high, though part of the shortfall was made up by imports. French exports of slate to the U.K. increased from 40,000 tons in 1898 to 105,000 tons in 1902.[19] After 1903 there was a depression in the slate industry which led to reductions in pay and job losses. New techniques in tile manufacture had reduced costs, making tiles more competitive.[20] The First World War hit the slate industry badly, particularly in Blaenau Ffestiniog where exports to Germany had been an important source of income. Cilgwyn, the oldest quarry in Wales, closed in 1914. In 1917 slate quarrying was declared a non-essential industry and a number of quarries were closed for the remainder of the war.[21] The demand for new houses after the end of the war brought back a measure of prosperity, but the depression in the 1930s led to cuts in production, with exports particularly hard hit.[22]

The quarries and mines made increasing use of mechanization from the turn of the century. This reduced the hard manual labour involved in extracting the slate, but produced much more slate dust than the old manual methods. This led to an increased incidence of silicosis to add to the physical danger of the work.

End of large-scale production (1939-2005)

[edit]The outbreak of World War 2 in 1939 led to a severe drop in trade. Part of the Manod (Cwt y Bugail) mine at Blaenau Ffestiniog was pressed into service to store art treasures from the National Gallery and the Tate Gallery. The number of men employed in the slate industry in North Wales dropped from 7,589 in 1939 to 3,520 by the end of the war.[23] In 1945 total production was only 70,000 tons a year, and fewer than 20 quarries were still open compared with 40 before the war.[24] The Nantlle Valley had been particularly hard hit, with only 350 workers employed in the entire district, compared with 1,000 in 1937.[25] Demand for slate was dropping as tiles were increasingly used for roofing, and imports from countries such as Portugal, France and Italy were increasing. There was some increased demand for slates to repair bombed buildings after the end of the war, but the use of slate for new buldings was banned, apart from the smallest sizes. This ban was lifted in 1949.[26]

Total production of slate in Wales declined from 54,000 tons in 1958 to 22,000 tons in 1970.[27] The Diffwys quarry at Blaenau Ffestiniog closed in 1955 after almost two centuries of operation.[28] The nearby Votty and Bowydd quarries closed in 1963. In 1969 the Dinorwic Quarry was closed, and over 300 quarrymen lost their jobs. The following year the Dorothea Quarry in the Nantlle Valley and the Braichgoch Slate Mine near Corris announced their closure, then in 1971 the Oakley Quarry at Blaenau Ffestiniog closed.[29] The Oakley Quarry was later reopened by another company. By 1972 the number of men employed in the North Wales slate industry was down to under 1,000.[30] There was little alternative employment in the slate producing areas, and the closures resulted in high unemployment and a drop in population as younger people moved away to find work. There was an increase in demand for slate in the 1980s, and although this came too late for many quarries there was still some production in the Blaenau Ffestiniog area at the Oakley, Llechwedd and Cwt y Bugail quarries, though the bulk of roofing slate production was at the Penrhyn Quarry.

Welsh slate today

[edit]

The Dinorwig Slate Quarry is now within the Padarn Country Park, Llanberis. The National Slate Museum is located in some of the quarry workshops. The museum reopened after receiving a £1.6 million grant from the National Lottery Fund and now has innovative displays featuring Victorian slateworkers' cottages that once stood at Tanygrisiau near Blaenau Ffestiniog. They were taken down and re-erected here. As well as many interesting exhibits, it has the multi-media display, To Steal a Mountain, showing the lives and work of the men who quarried slate here. The museum also has the largest working waterwheel in the United Kingdom, which is available for viewing via several walkways. The museum is also home to a replica lift that would have been used to carry eight slate wagons uphill and downhill.

In Blaenau Ffestiniog the Llechwedd Slate Caverns have been converted into a visitor attraction. Visitors can travel on the Miners Tramway or descend into the Deep Mine, via a funicular railway, to explore this former slate mine, learn how slate was extracted and processed and about the lives of the miners. The Deep Mine (opened in 1979) is accessed by Britain's steepest passenger railway, with a gradient of 1:1.8 or 30°. In its vast chambers, from which the rock has been extracted, sound and light is used to tell the story of the mine and mining. The Braich Goch slate mines at Corris have been converted into a tourist attraction named "King Arthur's Labyrinth" where visitors are taken underground by boat along a subterranean river. They then walk through the caverns to see audiovisual presentations of the Arthurian legends and stories from the Mabinogion and the tales of Taliesin. A number of the railways which carried the slates to the ports have been restored as tourist attractions, for example the Ffestiniog Railway and the Talyllyn Railway.

The Penrhyn Quarry is still producing slate, though at a much reduced capacity from its heyday at the end of the 1800s. It is currently owned and operated by Alfred McAlpine PLC, which also owns and carries out some operations at the Oakeley, Cwt y Bugail and Penyrorsedd mines at Blaenau Ffestiniog. The Greaves Welsh Slate Company produces roofing slates and other slate products from Llechwedd, and work also continues at the Berwyn Quarry near Llangollen. The final large-scale underground working to close was Maenofferen (which is associated with the Llechwedd tourist mine) around the start of the 21st century. The Wales Millennium Centre in Cardiff uses waste slate in many different colours in its design: purple slate from Penrhyn, blue from Cwt-y-Bugail, green from Nantlle, grey from Llechwedd, and black from Corris.

Cultural influences

[edit]The Welsh slate industry was essentially a Welsh-speaking industry. Most of the workforce in the main slate producing areas of North Wales were drawn from the local area, with little immigration from outside Wales. The industry had a considerable effect on the culture of the area and of Wales as a whole. The caban, the cabin where the quarrymen gathered for their lunch break, was often the scene of wide-ranging discussions, which were often formally minuted. A surviving set of minutes from a caban at the Llechwedd mine at Blaenau Ffestiniog for 1908-10 records discussions on Church Disestablishment, tariff reform and other political topics.[31] Eisteddfodau were held, poetry composed and discussed and most quarries had their own band, with the Oakley band particularly famous. Burn calculates that there are around fifty men judged worthy of an entry in the Dictionary of Welsh Biography who started their working lives as slate quarrymen, compared to only four owners.[32] A number of Welsh writers have drawn on the lives of the quarrymen for their material, for example the novels of T. Rowland Hughes. Chwalfa, translated into English as Out of their night (1954) has the Penrhyn Quarry dispute as a background, while Y cychwyn, translated as The beginning (1969) follows the apprenticeship of a young quarryman. Several novels by Kate Roberts give a picture of the area around Rhostryfan, where the slate industry was on a smaller scale and many of the quarrymen were also smallholders.

Notes

[edit]- ^ Jones p. 72

- ^ Roberts 1995 pp. 10-11

- ^ Lindsay p. 14

- ^ Lindsay p. 314

- ^ Lindsay p. 27

- ^ Lindsay p. 24

- ^ Lewis p. 6

- ^ Richards 1995 pp. 16-17

- ^ Richards pp. 21-22

- ^ Lewis p.5

- ^ Lindsey p. 117

- ^ Richards 1995 p. 93

- ^ Richards 1995 p. 122

- ^ Richards 1995 pp. 115-6

- ^ Richards 1995 p. 123

- ^ Quoted in Burn p. 10

- ^ Lindsay pp. 264-5

- ^ The question of whether the dispute was a lock-out or a strike can still arouse strong feelings in the Bethesda are a century later.

- ^ Burn p. 17

- ^ Lindsay p. 256-7

- ^ Lindsay p. 260

- ^ Lindsay p. 294

- ^ Lindsay p. 298

- ^ Richards 1995 p. 182

- ^ Richards 1995 pp. 183, 220-1

- ^ Richards pp. 183-4

- ^ Lindsay p. 303

- ^ Richards 1995 p. 185

- ^ Lindsay pp. 305-6

- ^ Lindsay p. 298

- ^ Burn p. 14

- ^ Burn p.15

References

[edit]- Burn, Michael. 1972. The age of slate. Quarry Tours Ltd., Blaenau Ffestiniog.

- Holmes, Alan. 1986. Slates from Abergynolwyn : the story of Bryneglwys Slate Quarry Gwynedd Archives Service. ISBN 0901337420

- Jones, R. Merfyn. 1981. The North Wales quarrymen, 1874-1922 Studies in Welsh history 4. University of Wales Press. ISBN 0-7083-0776-0

- Lewis, M.J.T. & M.C. Williams. 1987. Pioneers of Ffestiniog slate. Snowdonia National Park Study Centre, Plas Tan y Bwlch. ISBN 0-9512373-1-4

- Lindsay, Jean. 1974. A history of the North Wales slate industry. David and Charles. ISBN 0-7153-6264-x

- Richards, Alun John. 1994. Slate Quarrying at Corris. Gwasg Carreg Gwalch. ISBN 0863812791

- Richards, Alun John. 1995. Slate quarrying in Wales Gwasg Carreg Gwalch. ISBN 0-8638-1319-4

- Richards, Alun John. 1998. The slate quarries of Pembrokeshire Gwasg Carreg Gwalch. ISBN 0-863-81484-0