User:Peter Horn/Sandbox

Appearance

Odds and ends

[edit]- 1.5 L (3.17 US pt; 2.64 imp pt)

- 1.5 L (50.72 US fl oz; 52.79 imp fl oz)

- 1.54 L (54.20 imp fl oz; 52.07 US fl oz)

- 1 imperial gallon (160 imp fl oz; 154 US fl oz)

- 1 imperial gallon (160.00 imp fl oz; 153.72 US fl oz)

- 1 imperial gallon (160.0000 imp fl oz; 153.7216 US fl oz)

- 1 imperial gallon (160.00000000 imp fl oz; 153.72159046 US fl oz)

- 580 US gal (480 imp gal; 2,200 L), 290 US gal (240 imp gal; 1,100 L)

- 20,000 US dry qt (22,000 L), 20,000 US dry qt (620 US bsh; 22,000 L)

- 1 L (35.195 imp fl oz; 33.814 US fl oz)

- 1 L (35.2 imp fl oz; 33.8 US fl oz)

Pressure

[edit]- 200 psi (13.7895 bar; 1,378.95 kPa)

- 12 bar (1,200 kPa; 170 psi)

- 300 psi (21 bar; 2.1 MPa); 450 psi (31 bar; 3.1 MPa)

Mass

[edit]- 4 lb (1.8 kg)

- 4 ft 10+7⁄8 in (1,495.42 mm) 4 ft 11 in (1,498.60 mm) 4 ft 11 in (1,499 mm)

- 3-metre (9.8 ft) 3-metre (9 ft 10+1⁄8 in) 3,000 mm (9 ft 10+1⁄8 in)

- 4 ft 9 in (1,448 mm) See Template talk:Track gauge#Change a link

- 18 in (457 mm)

Flexi wagon

[edit]- 21,280 mm (69 ft 9+3⁄4 in), 21,280 mm (69 ft 9+13⁄16 in), 21,280 mm (69 ft 9+25⁄32 in), 21,280 mm (69 ft 9+51⁄64 in) Flexiwaggon say 21,280 mm (69 ft 10 in), 21,300 mm (69 ft 10+19⁄32 in) between truck centers.

- 17,500 mm (57 ft 5 in), 17,500 mm (57 ft 5 in), 17,500 mm (57 ft 4+31⁄32 in) and 17,500 mm (57 ft 4+31⁄32 in) Flexiwaggon loading bay.

- 2,400 mm (7 ft 10+1⁄2 in), 2,400 mm (7 ft 10+1⁄2 in), 2,400 mm (7 ft 10+1⁄2 in) and 2,400 mm (7 ft 10+1⁄2 in), loading bat width.

- 53 ft 0 in (16,154 mm) general max. trailer length, but some jurisdictions allow 56 ft 0 in (17,069 mm) max.

- 2,600 mm (8 ft 6+3⁄8 in), 2,600 mm (8 ft 6+3⁄8 in), 2,600 mm (8 ft 6+3⁄8 in), 2,600 mm (8 ft 6+23⁄64 in) trailer and container widths.

AAR Open Top Loading Rules Manual

[edit]- 9 ft 7 in (2,921 mm), 441.6836 ft (134,625.2 mm), 441.6836 ft (134.625 m), 441.6836 ft (134+5⁄8 m)

- 441.6836 ft or 134.625 m

- 59 ft 6 in (18,136 mm) Truck (bogie) pivot centers.

- 64 ft (19,507 mm) 66 ft (20,117 mm)

- 10 ft 8 in (3,251 mm)

- 41 ft 3 in (12,573 mm), AAR Plate B or 46 ft 3 in (14,097 mm), AAR Plate C, bogie centers.

- 8 ft 10+1⁄2 in (2.705 m)

REM

[edit]- 2,940 mm (9 ft 7+3⁄4 in) REM

- 9 ft 8 in (2,946.4 mm)

Drill

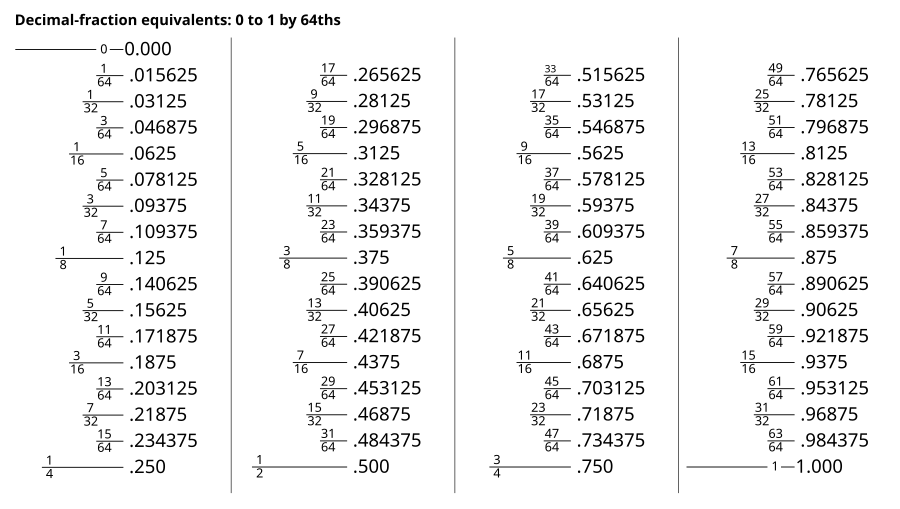

[edit]- 1⁄64 in (0.015625 in; 0.396875 mm)

- 1⁄32 in (0.03125 in; 0.79375 mm)

- 3⁄64 in (0.046875 in; 1.190625 mm)

- 1⁄16 in (0.0625 in; 1.5875 mm)

- 5⁄64 in (0.078125 in; 1.984375 mm)

- 3⁄32 in (0.09375 in; 2.38125 mm)

- 7⁄64 in (0.109375 in; 2.778125 mm)

- 1⁄8 in (0.125 in; 3.175 mm)

- 9⁄64 in (0.140625 in; 3.571875 mm)

- 5⁄32 in (0.15625 in; 3.96875 mm)

- 11⁄64 in (0.171875 in; 4.365625 mm)

- 3⁄16 in (0.1875 in; 4.7625 mm)

- 13⁄64 in (0.203125 in; 5.159375 mm)

- 7⁄32 in (0.21875 in; 5.55625 mm)

- 15⁄64 in (0.234375 in; 5.953125 mm)

- 1⁄4 in (0.250 in; 6.350 mm)

- 17⁄64 in (0.265625 in; 6.746875 mm)

- 9⁄32 in (0.28125 in; 7.14375 mm)

- 5⁄16 in (0.3125 in; 7.9375 mm)

- 21⁄64 in (0.328125 in; 8.334375 mm)

- 11⁄32 in (0.34375 in; 8.73125 mm)

- 23⁄64 in (0.359375 in; 9.128125 mm)

- 3⁄8 in (0.375 in; 9.525 mm)

- 25⁄64 in (0.390625 in; 9.921875 mm)

- 13⁄32 in (0.40625 in; 10.31875 mm)

- 13⁄32 in (0.40625 in; 10.31875 mm)

- 27⁄64 in (0.421875 in; 10.715625 mm)

- 7⁄16 in (0.4375 in; 11.1125 mm)

- 29⁄64 in (0.453125 in; 11.509375 mm)

- 15⁄32 in (0.46875 in; 11.90625 mm)

- 31⁄64 in (0.484375 in; 12.303125 mm)

- 1⁄2 in (0.500 in; 12.700 mm)

- 33⁄64 in (0.515625 in; 13.096875 mm)

- 17⁄32 in (0.53125 in; 13.49375 mm)

- 35⁄64 in (0.546875 in; 13.890625 mm)

- 9⁄16 in (0.5625 in; 14.2875 mm)

- 37⁄64 in (0.578125 in; 14.684375 mm)

- 19⁄32 in (0.59375 in; 15.08125 mm)

- 39⁄64 in (0.609375 in; 15.478125 mm)

- 5⁄8 in (0.625 in; 15.875 mm)

- 41⁄64 in (0.640625 in; 16.271875 mm)

- 21⁄32 in (0.65625 in; 16.66875 mm)

- 43⁄64 in (0.671875 in; 17.065625 mm)

- 11⁄16 in (0.6875 in; 17.4625 mm)

- 45⁄64 in (0.703125 in; 17.859375 mm)

- 23⁄32 in (0.71875 in; 18.25625 mm)

- 47⁄64 in (0.734375 in; 18.653125 mm)

- 3⁄4 in (0.750 in; 19.050 mm)

- 49⁄64 in (0.765625 in; 19.446875 mm)

- 25⁄32 in (0.78125 in; 19.84375 mm)

- 51⁄64 in (0.796875 in; 20.240625 mm)

- 13⁄16 in (0.8125 in; 20.6375 mm)

- 53⁄64 in (0.828125 in; 21.034375 mm)

- 27⁄32 in (0.84375 in; 21.43125 mm)

- 55⁄64 in (0.859375 in; 21.828125 mm)

- 7⁄8 in (0.875 in; 22.225 mm)

- 57⁄64 in (0.890625 in; 22.621875 mm)

- 29⁄32 in (0.90625 in; 23.01875 mm)

- 59⁄64 in (0.921875 in; 23.415625 mm)

- 15⁄16 in (0.9375 in; 23.8125 mm)

- 61⁄64 in (0.953125 in; 24.209375 mm)

- 31⁄32 in (0.96875 in; 24.60625 mm)

- 63⁄64 in (0.984375 in; 25.003125 mm)

- 63⁄64 in (0.984375 in; 25.003125 mm)

- 1 in (1.000 in; 25.400 mm)

Drill 2

[edit]

|

|

|

|

Pipe

[edit]| NPT - American Standard Pipe Thread Taper[1] | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size (inches) | TPI Threads per Inch |

pitch (inches or mm) |

Approximate Length of Thread (inches or mm) |

Approximate Number of Threads to be Cut |

Approximate Total thread Makeup, Hand and Wrench (inches or mm) |

Nominal Outside Pipe Diameter OD (inches or mm) |

Tap Drill (inches or mm) |

| 1/16" | 27 | 0.03037037 in or 0.7714 mm | 0.313 in or 7.950 mm | ||||

| 1/8" | 27 | 0.03037037 in or 0.7714 mm | 3⁄8 in or 9.525 mm | 10 | 1⁄4 in or 6.350 mm | 0.405 in or 10.287 mm | R 0.339 in or 8.6106 mm |

| 1/4" | 18 | 0.05555555 in or 1.4111 mm | 5⁄8 in or 15.875 mm | 11 | 3⁄8 in or 9.525 mm | 0.540 in or 13.716 mm | 7⁄16 in or 11.113 mm |

| 3/8" | 18 | 0.05555555 in or 1.4111 mm | 5⁄8 in or 15.875 mm | 11 | 3⁄8 in or 9.525 mm | 0.675 in or 17.145 mm | 37⁄64 in or 14.684 mm |

| 1/2" | 14 | 0.07142857 in or 1.8143 mm | 3⁄4 in or 19.0500 mm | 10 | 7⁄16 in or 11.1125 mm | 0.840 in or 21.3360 mm | 23⁄32 in or 18.2563 mm |

| 3/4" | 14 | 0.07142857 in or 1.8143 mm | 3⁄4 in or 19.0500 mm | 10 | 1⁄2 in or 12.7000 mm | 1.050 in or 26.6700 mm | 59⁄64 in or 23.4156 mm |

| 1" | 11-1/2 | 0.08695652 in or 2.2087 mm | 7⁄8 in or 22.2250 mm | 10 | 9⁄16 in or 14.2875 mm | 1.315 in or 33.4010 mm | 1+5⁄32 in or 29.3688 mm |

| 1-1/4" | 11-1/2 | 0.08695652 in or 2.2087 mm | 1 in or 25.4000 mm | 11 | 9⁄16 in or 14.2875 mm | 1.660 in or 42.1640 mm | 1+1⁄2 in or 38.1000 mm |

| 1-1/2" | 11-1/2 | 0.08695652 in or 2.2087 mm | 1 in or 25.4000 mm | 11 | 9⁄16 in or 14.2875 mm | 1.900 in or 48.2600 mm | 1+47⁄64 in or 44.0531 mm |

| 2" | 11-1/2 | 0.08695652 in or 2.2087 mm | 1 in or 25.4000 mm | 11 | 5⁄8 in or 15.8750 mm | 2.375 in or 60.3250 mm | 2+7⁄32 in or 56.3563 mm |

| 2-1/2" | 8 | 0.125 in or 3.1750 mm | 1+1⁄2 in or 38.1000 mm | 12 | 7⁄8 in or 22.2250 mm | 2.875 in or 73.0250 mm | 2+5⁄8 in or 66.6750 mm |

| 3" | 8 | 0.125 in or 3.1750 mm | 1+1⁄2 in or 38.1000 mm | 12 | 1 in or 25.4000 mm | 3.500 in or 88.9000 mm | 3+1⁄4 in or 82.5500 mm |

| 3-1/2" | 8 | 0.125 in or 3.1750 mm | 15⁄8 in or 15.8750 mm | 13 | 1+1⁄16 in or 26.9875 mm | 4.000 in or 101.6000 mm | 3+3⁄4 in or 95.2500 mm |

| 4" | 8 | 0.125 in or 3.1750 mm | 1+5⁄8 in or 41.2750 mm | 13 | 1+1⁄16 in or 26.9875 mm | 4.500 in or 114.3000 mm | 4+1⁄4 in or 107.9500 mm |

| 4 1/2" | 8 | 0.125 in or 3.1750 mm | 5.000 in or 127.0000 mm | 4+3⁄4 in or 120.6500 mm | |||

| 5" | 8 | 0.125 in or 3.1750 mm | 1+3⁄4 in or 44.4500 mm | 14 | 1+3⁄16 in or 30.1625 mm | 5.563 in or 141.3002 mm | 5+9⁄32 in or 134.1438 mm |

| 6" | 8 | 0.125 in or 3.1750 mm | 1+3⁄4 in or 44.4500 mm | 14 | 1+3⁄16 in or 30.1625 mm | 6.625 in or 168.2750 mm | 6+11⁄32 in or 161.1313 mm |

| 8" | 8 | 0.125 in or 3.1750 mm | 1+7⁄8 in or 47.6250 mm | 15 | 1+5⁄16 in or 33.3375 mm | 8.625 in or 219.0750 mm | |

| 10" | 8 | 0.125 in or 3.1750 mm | 2 in or 50.8000 mm | 16 | 1+1⁄2 in or 38.1000 mm | 10.750 in or 273.0500 mm | |

| 12" | 8 | 0.125 in or 3.1750 mm | 2+1⁄8 in or 53.9750 mm | 17 | 1+5⁄8 in or 41.2750 mm | 12.750 in or 323.8500 mm | |

| 14" | 8 | 0.125 in or 3.1750 mm | 14.000 in or 355.6000 mm | ||||

| 16" | 8 | 0.125 in or 3.1750 mm | 16.000 in or 406.4000 mm | ||||

B

[edit]| NPT - American Standard Pipe Thread Taper[2] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size (inches) |

TPI No of Threads per inch |

pitch inch |

mm | Approximate Length of Thread inch |

mm | Approximate Number of Threads to be Cut |

Approximate Total thread Makeup Hand and Wrench inch |

mm | Nominal Outside Pipe Diameter OD inch |

mm | Tap Drill inch |

mm |

| 1/16" | 27 | 0.03037037 | 0.7714 | 0.313 | 7.950 | |||||||

| 1/8" | 27 | 0.03037037 | 0.7714 | 3⁄8 | 9.525 | 10 | 1⁄4 | 6.350 | 0.405 | 10.287 | 0.339 | 8.6106 |

| 1/4" | 18 | 0.05555555 | 1.4111 | 5⁄8 | 15.875 | 11 | 3⁄8 | 9.525 | 0.540 | 13.716 | 7⁄16 | 11.113 |

| 3/8" | 18 | 0.05555555 | 1.4111 | 5⁄8 | 15.875 | 11 | 3⁄8 | 9.525 | 0.675 | 17.145 | 37⁄64 | 14.684 |

| 1/2" | 14 | 0.07142857 | 1.8143 | 3⁄4 | 19.0500 | 10 | 7⁄16 | 11.1125 | 0.840 | 21.3360 | 23⁄32 | 18.2563 |

| 3/4" | 14 | 0.07142857 | 1.8143 | 3⁄4 | 19.0500 | 10 | 1⁄2 | 12.7000 | 1.050 | 26.6700 | 59⁄64 | 23.4156 |

| 1" | 11-1/2 | 0.08695652 | 2.2087 | 7⁄8 | 22.2250 | 10 | 9⁄16 | 14.2875 | 1.315 | 33.4010 | 1+5⁄32 | 29.3688 |

| 1-1/4" | 11-1/2 | 0.08695652 | 2.2087 | 1 | 25.4000 | 11 | 9⁄16 | 14.2875 | 1.660 | 42.1640 | 1+1⁄2 | 38.1000 |

| 1-1/2" | 11-1/2 | 0.08695652 | 2.2087 | 1 | 25.4000 | 11 | 9⁄16 | 14.2875 | 1.900 | 48.2600 | 1+47⁄64 | 44.0531 |

| 2" | 11-1/2 | 0.08695652 | 2.2087 | 1 | 25.4000 | 11 | 5⁄8 | 15.8750 | 2.375 | 60.3250 | 2+7⁄32 | 56.3563 |

| 2-1/2" | 8 | 0.125 | 3.1750 | 1+1⁄2 | 38.1000 | 12 | 7⁄8 | 22.2250 | 2.875 | 73.0250 | 2+5⁄8 | 66.6750 |

| 3" | 8 | 0.125 | 3.1750 | 1+1⁄2 | 38.1000 | 12 | 1 | 25.4000 | 3.500 | 88.9000 | 3+1⁄4 | 82.5500 |

| 3-1/2" | 8 | 0.125 | 3.1750 | 5⁄8 | 15.8750 | 13 | 1+1⁄16 | 26.9875 | 4.000 | 101.6000 | 3+3⁄4 | 95.2500 |

| 4" | 8 | 0.125 | 3.1750 | 1+5⁄8 | 41.2750 | 13 | 1+1⁄16 | 26.9875 | 4.500 | 114.3000 | 4+1⁄4 | 107.9500 |

| 4 1/2" | 8 | 0.125 | 3.1750 | 5.000 | 127.0000 | 4+3⁄4 | 120.6500 | |||||

| 5" | 8 | 0.125 | 3.1750 | 1+3⁄4 | 44.4500 | 14 | 1+3⁄16 | 30.1625 | 5.563 | 141.3002 | 5+9⁄32 | 134.1438 |

| 6" | 8 | 0.125 | 3.1750 | 1+3⁄4 | 44.4500 | 14 | 1+3⁄16 | 30.1625 | 6.625 | 168.2750 | 6+11⁄32 | 161.1313 |

| 8" | 8 | 0.125 | 3.1750 | 1+7⁄8 | 47.6250 | 15 | 1+5⁄16 | 33.3375 | 8.625 | 219.0750 | ||

| 10" | 8 | 0.125 | 3.1750 | 2 | 50.8000 | 16 | 1+1⁄2 | 38.1000 | 10.750 | 273.0500 | ||

| 12" | 8 | 0.125 | 3.1750 | 2+1⁄8 | 53.9750 | 17 | 1+5⁄8 | 41.2750 | 12.750 | 323.8500 | ||

| 14" | 8 | 0.125 | 3.1750 | 14.000 | 355.6000 | |||||||

| 16" | 8 | 0.125 | 3.1750 | 16.000 | 406.4000 | |||||||

| NPS[1] | DN mm |

OD inches (millimeters) |

Wall thickness inches (millimeters) | |||

|---|---|---|---|---|---|---|

| SCH 5 | SCH 10 | SCH 30 | SCH 40/STD | |||

| ⅛ | 6 | 0.405 in (10.29 mm) | 0.035 in (0.889 mm) | 0.049 in (1.245 mm) | 0.057 in (1.448 mm) | 0.068 in (1.727 mm) |

| ¼ | 8 | 0.540 in (13.72 mm) | 0.049 in (1.245 mm) | 0.065 in (1.651 mm) | 0.073 in (1.854 mm) | 0.088 in (2.235 mm) |

| ⅜ | 10 | 0.675 in (17.15 mm) | 0.049 in (1.245 mm) | 0.065 in (1.651 mm) | 0.073 in (1.854 mm) | 0.091 in (2.311 mm) |

| ½ | 15 | 0.840 in (21.34 mm) | 0.065 in (1.651 mm) | 0.083 in (2.108 mm) | — | 0.109 in (2.769 mm) |

| ¾ | 20 | 1.050 in (26.67 mm) | 0.065 in (1.651 mm) | 0.083 in (2.108 mm) | — | 0.113 in (2.870 mm) |

| 1 | 25 | 1.315 in (33.40 mm) | 0.065 in (1.651 mm) | 0.109 in (2.769 mm) | — | 0.133 in (3.378 mm) |

| 1¼ | 32 | 1.660 in (42.16 mm) | 0.065 in (1.651 mm) | 0.109 in (2.769 mm) | 0.117 in (2.972 mm) | 0.140 in (3.556 mm) |

| 1½ | 40 | 1.900 in (48.26 mm) | 0.065 in (1.651 mm) | 0.109 in (2.769 mm) | 0.125 in (3.175 mm) | 0.145 in (3.683 mm) |

| 2 | 50 | 2.375 in (60.33 mm) | 0.065 in (1.651 mm) | 0.109 in (2.769 mm) | 0.125 in (3.175 mm) | 0.154 in (3.912 mm) |

| 2½ | 65 | 2.875 in (73.03 mm) | 0.083 in (2.108 mm) | 0.120 in (3.048 mm) | 0.188 in (4.775 mm) | 0.203 in (5.156 mm) |

| 3 | 80 | 3.500 in (88.90 mm) | 0.083 in (2.108 mm) | 0.120 in (3.048 mm) | 0.188 in (4.775 mm) | 0.216 in (5.486 mm) |

| 3½ | 90 | 4.000 in (101.60 mm) | 0.083 in (2.108 mm) | 0.120 in (3.048 mm) | 0.188 in (4.775 mm) | 0.226 in (5.740 mm) |

| NPS[1] | DN mm |

OD inches (millimeters) |

Wall thickness inches (millimeters) | |||

|---|---|---|---|---|---|---|

| SCH 80 | SCH 120 | SCH 160 | XXS | |||

| ⅛ | 6 | 0.405 in (10.29 mm) | 0.095 in (2.413 mm) | — | — | — |

| ¼ | 8 | 0.540 in (13.72 mm) | 0.119 in (3.023 mm) | — | — | — |

| ⅜ | 10 | 0.675 in (17.15 mm) | 0.126 in (3.200 mm) | — | — | — |

| ½ | 15 | 0.840 in (21.34 mm) | 0.147 in (3.734 mm) | — | — | 0.294 in (7.468 mm) |

| ¾ | 20 | 1.050 in (26.67 mm) | 0.154 in (3.912 mm) | — | — | 0.308 in (7.823 mm) |

| 1 | 25 | 1.315 in (33.40 mm) | 0.179 in (4.547 mm) | — | — | 0.358 in (9.093 mm) |

| 1¼ | 32 | 1.660 in (42.16 mm) | 0.191 in (4.851 mm) | — | — | 0.382 in (9.703 mm) |

| 1½ | 40 | 1.900 in (48.26 mm) | 0.200 in (5.080 mm) | — | 0.400 in (10.160 mm) | — |

| 2 | 50 | 2.375 in (60.33 mm) | 0.218 in (5.537 mm) | 0.250 in (6.350 mm) | 0.343 in (8.712 mm) | 0.436 in (11.074 mm) |

| 2½ | 65 | 2.875 in (73.03 mm) | 0.276 in (7.010 mm) | 0.300 in (7.620 mm) | 0.375 in (9.525 mm) | 0.552 in (14.021 mm) |

| 3 | 80 | 3.500 in (88.90 mm) | 0.300 in (7.620 mm) | 0.350 in (8.890 mm) | 0.438 in (11.125 mm) | 0.600 in (15.240 mm) |

| 3½ | 90 | 4.000 in (101.60 mm) | 0.318 in (8.077 mm) | — | — | 0.636 in (16.154 mm) |

| Nominal Size | Class | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A & B | A | B | C & D | C | D | |||||

| Outer Diameter [in (mm)] |

Wall Thickness [in (mm)] |

Internal Diameter [in (mm)] |

Wall Thickness [in (mm)] |

Internal Diameter [in (mm)] |

Outer Diameter [in (mm)] |

Wall Thickness [in (mm)] |

Internal Diameter [in (mm)] |

Wall Thickness [in (mm)] |

Internal Diameter [in (mm)] | |

| 3 | 3.76 (95.504) | 0.38 (9.652) | 3.00 (76.200) | 0.38 (9.652) | 3.00 (76.200) | 3.76 (95.504) | 0.38 (9.652) | 3.00 (76.200) | 0.40 (10.160) | 2.96 (75.184) |

| 4 | 4.80 (121.920) | 0.39 (9.906) | 4.02 (102.108) | 3.76 (95.504) | 4.02 (102.108) | 4.80 (121.920) | 0.40 (10.160) | 4.00 (101.600) | 0.46 (11.684) | 3.88 (98.552) |

| 5 | 5.90 (149.860) | 0.41 (10.414) | 5.08 (129.032) | 0.41 (10.414) | 5.08 (129.032) | 5.90 (149.860) | 0.45 (11.430) | 5.00 (127.000) | 0.52 (13.208) | 4.86 (123.444) |

| 6 | 6.98 (177.292) | 0.43 (10.922) | 6.12 (155.448) | 0.43 (10.922) | 6.12 (155.448) | 6.98 (177.292) | 0.49 (12.446) | 6.00 (152.400) | 0.57 (14.478) | 5.84 (148.336) |

| 7 | 8.06 (204.724) | 0.45 (11.430) | 7.16 (181.864) | 0.45 (11.430) | 7.16 (181.864) | 8.06 (204.724) | 0.53 (13.462) | 7.00 (177.800) | 0.61 (15.494) | 6.84 (173.736) |

| 8 | 9.14 (232.156) | 0.47 (11.938) | 8.20 (208.280) | 0.47 (11.938) | 8.20 (208.280) | 9.14 (232.156) | 0.57 (14.478) | 8.00 (203.200) | 0.65 (16.510) | 7.84 (199.136) |

| 9 | 10.20 (259.080) | 0.48 (12.192) | 9.22 (234.188) | 0.49 (12.446) | 9.22 (234.188) | 10.20 (259.080) | 0.60 (15.240) | 9.00 (228.600) | 0.69 (17.526) | 8.82 (224.028) |

| 10 | 11.26 (286.004) | 0.52 (13.208) | 10.22 (259.588) | 0.52 (13.208) | 10.22 (259.588) | 11.26 (286.004) | 0.63 (16.002) | 10.00 (254.000) | 0.73 (18.542) | 9.80 (248.920) |

| 12 | 13.14 (333.756) | 0.55 (13.970) | 12.04 (305.816) | 0.57 (14.478) | 12.00 (304.800) | 13.60 (345.440) | 0.69 (17.526) | 12.22 (310.388) | 0.80 (20.320) | 12.00 (304.800) |

| 14 | 15.22 (386.588) | 0.57 (14.478) | 14.08 (357.632) | 0.61 (15.494) | 14.00 (355.600) | 15.72 (399.288) | 0.75 (19.050) | 14.22 (361.188) | 0.86 (21.844) | 14.00 (355.600) |

| 15 | 16.26 (413.004) | 0.59 (14.986) | 15.08 (383.032) | 0.63 (16.002) | 15.00 (381.000) | 16.78 (426.212) | 0.77 (19.558) | 15.24 (387.096) | 0.89 (22.606) | 15.00 (381.000) |

| 16 | 17.30 (439.420) | 0.60 (15.240) | 16.10 (408.940) | 0.65 (16.510) | 16.00 (406.400) | 17.84 (453.136) | 0.80 (20.320) | 16.24 (412.496) | 0.92 (23.368) | 16.00 (406.400) |

| 18 | 19.38 (492.252) | 0.63 (16.002) | 18.12 (460.248) | 0.69 (17.526) | 18.00 (457.200) | 19.96 (506.984) | 0.85 (21.590) | 18.26 (463.804) | 0.98 (24.892) | 18.00 (457.200) |

| 20 | 21.46 (545.084) | 0.65 (16.510) | 20.16 (512.064) | 0.73 (18.542) | 20.00 (508.000) | 22.06 (560.324) | 0.89 (22.606) | 20.28 (515.112) | 1.03 (26.162) | 20.00 (508.000) |

| 21 | 22.50 (571.500) | 0.67 (17.018) | 21.16 (537.464) | 0.75 (19.050) | 21.00 (533.400) | 23.12 (587.248) | 0.92 (23.368) | 21.28 (540.512) | 1.03 (26.162) | 21.00 (533.400) |

| 24 | 25.60 (650.240) | 0.71 (18.034) | 24.18 (614.172) | 0.80 (20.320) | 24.00 (609.600) | 26.26 (667.004) | 0.98 (24.892) | 24.30 (617.220) | 1.13 (28.702) | 24.00 (609.600) |

| 27 | 28.70 (728.980) | 0.75 (19.050) | 27.20 (690.880) | 0.85 (21.590) | 27.00 (685.800) | 29.40 (746.760) | 1.04 (26.416) | 27.32 (693.928) | 1.20 (30.480) | 27.00 (685.800) |

| 30 | 32.52 (826.008) | 0.79 (20.066) | 30.94 (785.876) | 0.89 (22.606) | 30.74 (780.796) | 32.52 (826.008) | 1.09 (27.686) | 30.34 (770.636) | 1.26 (32.004) | 30.00 (762.000) |

| 33 | 35.66 (905.764) | 0.83 (21.082) | 34.00 (863.600) | 0.94 (23.876) | 33.78 (858.012) | 35.66 (905.764) | 1.15 (29.210) | 33.36 (847.344) | 1.33 (33.782) | 33.00 (838.200) |

| 36 | 38.76 (984.504) | 0.87 (22.098) | 37.02 (940.308) | 0.98 (24.892) | 36.80 (934.720) | 38.76 (984.504) | 1.20 (30.480) | 36.36 (923.544) | 1.38 (35.052) | 36.00 (914.400) |

| 40 | 42.92 (1,090.168) | 0.92 (23.368) | 41.08 (1,043.432) | 1.03 (26.162) | 40.86 (1,037.844) | 42.92 (1,090.168) | 1.26 (32.004) | 40.40 (1,026.160) | 1.46 (37.084) | 40.00 (1,016.000) |

| 42 | 45.00 (1,143.000) | 0.95 (24.130) | 43.10 (1,094.740) | 1.06 (26.924) | 42.88 (1,089.152) | 45.00 (1,143.000) | 1.30 (33.020) | 42.40 (1,076.960) | 1.50 (38.100) | 42.00 (1,066.800) |

| 45 | 48.10 (1,221.740) | 0.99 (25.146) | 46.12 (1,171.448) | 1.09 (27.686) | 45.92 (1,166.368) | 48.10 (1,221.740) | 1.35 (34.290) | 45.40 (1,153.160) | 1.55 (39.370) | 45.00 (1,143.000) |

| 48 | 51.20 (1,300.480) | 1.03 (26.162) | 49.14 (1,248.156) | 1.13 (28.702) | 48.94 (1,243.076) | 51.20 (1,300.480) | 1.38 (35.052) | 48.44 (1,230.376) | 1.68 (42.672) | 47.84 (1,215.136) |

- ^ a b Table of Pipe Schedules from EngineersEdge.com. Table shows additional schedules, sizes and sizes greater than 24".

| Pipe Size | Outside Diameter [in (mm)] |

|---|---|

| 3 | 3.96 (100.584) |

| 4 | 4.80 (121.92) |

| 6 | 6.90 (175.26) |

| 8 | 9.05 (229.87) |

| 10 | 11.10 (281.94) |

| 12 | 13.20 (335.28) |

| Pipe Size | Outside Diameter [in (mm)] |

|---|---|

| 14 | 15.30 (388.62) |

| 16 | 17.40 (441.96) |

| 18 | 19.50 (495.3) |

| 20 | 21.60 (548.64) |

| 24 | 25.80 (655.32) |

| 30 | 32.00 (812.8) |

| DN | Outside Diameter [mm (in)] |

Wall thickness [mm (in)] | ||

|---|---|---|---|---|

| Class 40 | K9 | K10 | ||

| 40 | 56 (2.205) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 50 | 66 (2.598) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 60 | 77 (3.031) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 65 | 82 (3.228) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 80 | 98 (3.858) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 100 | 118 (4.646) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 125 | 144 (5.669) | 4.8 (0.189) | 6.0 (0.236) | 6.0 (0.236) |

| 150 | 170 (6.693) | 5.0 (0.197) | 6.0 (0.236) | 6.5 (0.256) |

| 200 | 222 (8.740) | 8.4 (0.331) | 6.3 (0.248) | 7.0 (0.276) |

| 250 | 274 (10.787) | 5.8 (0.228) | 6.8 (0.268) | 7.5 (0.295) |

| 300 | 326 (12.835) | 6.2 (0.244) | 7.2 (0.283) | 8.0 (0.315) |

| 350 | 378 (14.882) | 7.0 (0.276) | 7.7 (0.303) | 8.5 (0.335) |

| 400 | 429 (16.890) | 7.8 (0.307) | 8.1 (0.319) | 9.0 (0.354) |

| 450 | 480 (18.898) | - | 8.6 (0.339) | 9.5 (0.374) |

| DN | Outside Diameter [mm (in)] |

Wall thickness [mm (in)] | ||

|---|---|---|---|---|

| Class 40 | K9 | K10 | ||

| 500 | 532 (20.945) | - | 9.0 (0.354) | 10.0 (0.394) |

| 600 | 635 (25.000) | - | 9.9 (0.390) | 11.1 (0.437) |

| 700 | 738 (29.055) | - | 10.9 (0.429) | 12.0 (0.472) |

| 800 | 842 (33.150) | - | 11.7 (0.461) | 13.0 (0.512) |

| 900 | 945 (37.205) | - | 12.9 (0.508) | 14.1 (0.555) |

| 1000 | 1,048 (41.260) | - | 13.5 (0.531) | 15.0 (0.591) |

| 1100 | 1,152 (45.354) | - | 14.4 (0.567) | 16.0 (0.630) |

| 1200 | 1,255 (49.409) | - | 15.3 (0.602) | 17.0 (0.669) |

| 1400 | 1,462 (57.559) | - | 17.1 (0.673) | 19.0 (0.748) |

| 1500 | 1,565 (61.614) | - | 18.0 (0.709) | 20.0 (0.787) |

| 1600 | 1,668 (65.669) | - | 18.9 (0.744) | 51.0 (2.008) |

| 1800 | 1,875 (73.819) | - | 20.7 (0.815) | 23.0 (0.906) |

| 2000 | 2,082 (81.969) | - | 22.5 (0.886) | 25.0 (0.984) |

| Nominal Size (DN) | Outside Diameter [mm (in)] |

Nominal Wall Thickness [mm (in)] |

Flange Class | |

|---|---|---|---|---|

| PN 20 | PN 35 | |||

| 100 | 122 (4.803) | - | 5.0 (0.197) | 7.0 |

| 150 | 177 (6.969) | - | 5.0 (0.197) | 8.0 |

| 200 | 232 (9.134) | - | 5.0 (0.197) | 8.0 |

| 225 | 259 (10.197) | 5.0 (0.197) | 5.2 (0.205) | 9.0 |

| 250 | 286 (11.260) | 5.0 (0.197) | 5.6 (0.220) | 9.0 |

| 300 | 345 (13.583) | 5.0 (0.197) | 6.3 (0.248) | 10.0 |

| Nominal Size (DN) | Outside Diameter [mm (in)] |

Nominal Wall Thickness [mm (in)] |

Flange Class | |

|---|---|---|---|---|

| PN 20 | PN 35 | |||

| 375 | 426 (16.772) | 5.1 (0.201) | 7.3 (0.287) | 10.0 |

| 450 | 507 (19.961) | 5.6 (0.220) | 8.3 (0.327) | 11.0 |

| 500 | 560 (22.047) | 6.0 (0.236) | 9.0 (0.354) | 12.0 |

| 600 | 667 (26.260) | 6.8 (0.268) | 310.3 (0.406) | 13.0 |

| 750 | 826 (32.520) | 7.9 (0.311) | 12.2 (0.480) | 15.0 |

| Thread nominal size | Outer diameter [mm (in)] |

Threads per inch (TPI) |

Pitch [in (mm)] |

Inner diameter [mm (in)] |

Cable diameter [mm (in)] |

|---|---|---|---|---|---|

| PG7 | 12.5 (0.492) | 20 | 0.05 (1.270) | 11.28 (0.444) | 3 (0.118) to 6.5 (0.256) |

| PG9 | 15.5 (0.610) | 18 | 0.05556 (1.4112) | 13.86 (0.546) | 4 (0.157) to 8 (0.315) |

| PG11 | 18.6 (0.732) | 18 | 0.05556 (1.4112) | 17.26 (0.680) | 5 (0.197) to 10 (0.394) |

| PG13.5 | 20.4 (0.803) | 18 | 0.05556 (1.4112) | 19.06 (0.750) | 6 (0.236) to 12 (0.472) |

| PG16 | 22.5 (0.886) | 18 | 0.05556 (1.4112) | 21.16 (0.833) | 10 (0.394) to 14 (0.551) |

| PG21 | 28.3 (1.114) | 16 | 0.0625 (1.5875) | 26.78 (1.054) | 13 (0.512) to 18 (0.709) |

| PG29 | 37.0 (1.457) | 16 | 0.0625 (1.5875) | 35.48 (1.397) | 18 (0.709) to 25 (0.984) |

| PG36 | 47.0 (1.850) | 16 | 0.0625 (1.5875) | 45.48 (1.791) | |

| PG42 | 54.0 (2.126) | 16 | 0.0625 (1.5875) | 52.48 (2.066) | |

| PG48 | 59.3 (2.335) | 16 | 0.0625 (1.5875) | 57.78 (2.275) |

- 3 to 6.5 (0.118 to 0.256)

Bolt strength

[edit]Screw#Mechanical classifications

Imperial

[edit]| Head markings and properties for inch-system hex-head cap screws[1] | ||||||

|---|---|---|---|---|---|---|

| Head marking | Grade, material, and condition | Nominal size range (in) | Proof strength (ksi or MPa) | Yield strength, min. ksi or MPa | Tensile strength, min. ksi or MPa | Core hardness (Rockwell) |

|

SAE Grade 0[2][3] | Strength and hardness is not specified | ||||

| SAE grade 1 ASTM A307[4] Low carbon steel |

1⁄4–1+1⁄2 | 33 or 230 | 60 or 410 | B70–100 | ||

| ASTM A307 - Grade B[4] Low or medium carbon steel |

1⁄4–4 | 60 or 410 minimum 100 or 690 maximum |

B69–95 | |||

| SAE grade 2 Low or medium carbon steel |

1⁄4–3⁄4 | 55 (380)* | 57 (390)* | 74 (510)* | B80–100[5] | |

| Greater than 3⁄4 | 33 (230)* | 36 (250)* | 60 (410)* | B70–100[5] | ||

| SAE grade 4[6] Medium carbon steel; cold worked |

1⁄4–1-1⁄2 | 100 (690)* | 115 (790)* | |||

|

SAE grade 3[4] Medium carbon steel; cold worked |

1⁄4–1 | 85 (590)* | 100 (690)* | B70–100 | |

|

SAE grade 5 Medium carbon steel; quench and tempered |

1⁄4–1 (inc.) | 85 (590)* | 92 (630)* | 120 (830)* | C25–34[5] |

| 1–1-1⁄2 | 74 (510)* | 81 (560)* | 105 (720)* | C19–30[5] | ||

| ASTM A449 - Type 1[4] Medium carbon steel; quench and tempered |

1–1-1⁄2 (inc.) | 74 (510)* | 105 (720)* | C19–30 | ||

| 1-1⁄2–3 | 55 (380)* | 90 (620)* | Brinell 183–235 | |||

|

SAE grade 5.1[7] Low or medium carbon steel; quench and tempered |

No. 6–1⁄2 | 85 (590)* | 120 (830)* | C25–40 | |

|

SAE grade 5.2[7] Low carbon martensitic steel; quench and tempered |

1⁄4–1 | 85 (590)* | 120 (830)* | C26–36 | |

| ASTM A449 - Type 2[7] Low carbon martensitic steel; quench and tempered |

C25–34 | |||||

or or |

ASTM A325 - Type 1[4] Medium carbon steel; quench and tempered |

1⁄2–1 (inc.) | 85 (590)* | 92 (630)*[6] | 120 (830)* | C24–35 |

| 1–1-1⁄2 | 74 (510)* | 82 (570)*[6] | 105 (720)* | C19–31 | ||

[8] [8] |

ASTM A325 - Type 3[4] Atmospheric corrosion resistant steel; quench and tempered |

1⁄2–1 | 85 (590)* | 92 (630)*[6] | 120 (830)* | C24–35 |

| 1–1-1⁄2 | 74 (510)* | 82 (570)*[6] | 105 (720)* | C19–31 | ||

|

ASTM A354 - Grade BC[4] Medium carbon alloy steel; quench and tempered |

1⁄4–2-1⁄2 (inc.) | 105 (720)* | 109 (750)*[6] | 125 (860)* | C26–36 |

| 2-1⁄2–4 | 95 (660)* | 99 (680)*[6] | 115 (790)* | C22–33 | ||

|

SAE grade 7 Medium carbon alloy steel; quench and tempered |

1⁄4–1-1⁄2 | 105 (720)* | 115 (790)* | 133 (920)* | |

|

SAE grade 8 Medium carbon alloy steel; quench and tempered |

1⁄4–1-1⁄2 | 120 (830)* | 130 (900)* | 150 (1,000)* | C32–38[5] |

|

ASTM A354 - Grade BD[9] | 1⁄4–2-1⁄2 (inc.) | 120 (830)* | 130 (900)*[9] | 150 (1,000)* | C33–39 |

|

2-1⁄2–4 | 105 (720)* | 115 (790)*[9] | 140 (970)* | C31–39 | |

|

SAE grade 8.2[5] Medium carbon boron martensitic steel; fully kilned, fine grain, quench and tempered |

1⁄4–1 | 120 (830)* | 150 (1,000)* | C33–39 | |

|

ASTM A490 - Type 1[4] Medium carbon alloy steel; quench and tempered |

1⁄2–1-1⁄2 | 120 (830)* | 130 (900)*[6] | 150 (1,000)* minimum 170 (1,200)* maximum |

C33–38 |

[8] [8] |

ASTM A490 - Type 3[4] Atmospheric corrosion resistant steel; quench and tempered | |||||

| 18-8 Stainless Stainless steel with 17–19% chromium and 8–13% nickel |

1⁄4–5⁄8 (inc.) | 40 (280)* minimum 80 (550)* – 90 (620)* typical |

100 (690)* – 125 (860)* typical | |||

| 5⁄8–1 (inc.) | 40 (280)* minimum 45 (310)* – 70 (480)* typical |

100 (690)* typical | ||||

| Over 1 | 80 (550)* – 90 (620)* typical | |||||

Metric

[edit]| Head markings and properties for metric hex-head cap screws[10] | ||||||

|---|---|---|---|---|---|---|

| Head marking | Grade, material, and condition | Nominal size range (mm) | Proof strength (MPa/ksi) | Yield strength, min. (MPa/ksi) | Tensile strength, min. (MPa/ksi) | Core hardness (Rockwell) |

|

Class 3.6[11] | 1.6–36 | 180 (26)* | 190 (28)* | 330 (48)* | B52–95 |

|

Class 4.6 Low or medium carbon steel |

5–100 | 225 (32.6)* | 240 (35)* | 400 (58)* | B67–95 |

|

Class 4.8 Low or medium carbon steel; fully or partially annealed |

1.6–16 | 310 (45)* | 340 (49)* | 420 (61)* | B71–95 |

|

Class 5.8 Low or medium carbon steel; cold worked |

5–24 | 380 (55)* | 420 (61)* | 520 (75)* | B82–95 |

|

Class 8.8[1] Medium carbon steel; quench and tempered |

Under 16 (inc.) | 580 (84)* | 640 (93)* | 800 (120)* | |

| 17–72 | 600 (87)* | 660 (96)* | 830 (120)* | C23–34 | ||

|

Class 8.8 low carbon Low carbon boron steel; quench and tempered | |||||

|

Class 8.8.3[12] Atmospheric corrosion resistant steel; quench and tempered | |||||

|

ASTM A325M - Type 1[13][14] Medium carbon steel; quench and tempered |

12–36 | ||||

|

ASTM A325M - Type 3[13][14] Atmospheric corrosion resistant steel; quench and tempered | |||||

|

Class 9.8 Medium carbon steel; quench and tempered |

1.6–16 | 650 (94)* | 720 (104)* | 900 (130)* | C27–36 |

|

Class 9.8 low carbon Low carbon boron steel; quench and tempered | |||||

|

Class 10.9 Alloy steel; quench and tempered |

5–100 | 830 (120)* | 940 (136)* | 1,040 (151)* | C33–39 |

|

Class 10.9 low carbon Low carbon boron steel; quench and tempered | |||||

|

Class 10.9.3[12] Atmospheric corrosion resistant steel; quench and tempered | |||||

|

ASTM A490M - Type 1[13][15] Alloy steel; quench and tempered |

12–36 | ||||

|

ASTM A490M - Type 3[13][15] Atmospheric corrosion resistant steel; quench and tempered | |||||

|

Class 12.9 Alloy steel; quench and tempered |

1.6–100 | 970 (141)* | 1,100 (160)* | 1,220 (177)* | C38–44 |

|

A2[1] Stainless steel with 17–19% chromium and 8–13% nickel |

Up to 20 | 210 (30)* minimum 450 (65)* typical |

500 (73)* minimum 700 (100)* typical | ||

| ISO 3506-1 A2-50[citation needed] 304 stainless steel-class 50 (annealed) |

210 (30)* | 500 (73)* | ||||

| ISO 3506-1 A2-70[citation needed] 304 stainless steel-class 70 (cold worked) |

450 (65)* | 700 (100)* | ||||

| ISO 3506-1 A2-80[citation needed] 304 stainless steel-class 80 |

600 (87)* | 800 (120)* | ||||

- ^ a b c Bolt grade markings and strength chart, retrieved 2009-05-29.

- ^ Mechanical Methods of Joining, retrieved 2009-06-06.

- ^ Grade Markings for Steel Bolts and Screws, retrieved 2009-06-06.

- ^ a b c d e f g h i Grade Markings: Carbon Steel Bolts, retrieved 2009-05-30.

- ^ a b c d e f Hardware, bulk — Tehttps://en.wikipedia.org/w/index.php?title=User:Peter_Horn/Sandbox&action=submitchnical information, retrieved 2009-05-30.

{{citation}}: External link in|title= - ^ a b c d e f g h ASTM, SAE and ISO grade markings and mechanical properties for steel fasteners, retrieved 2009-06-06.

- ^ a b c Fastener identification marking (PDF), retrieved 2009-06-23.

- ^ a b Other markings may be used to denote atmospheric corrosion resistant material

- ^ a b c FastenalTechnicalReferenceGuide (PDF), retrieved 2010-04-30.

- ^ Metric Handbook, retrieved 2009-06-06.

- ^ Mechanical properties of bolts, screws, and studs according DIN-ISO 898, part 1 (PDF), retrieved 2009-06-06.

- ^ a b ASTM F568M - 07, 2007, retrieved 2009-06-06.

- ^ a b c d Metric structural fasteners, retrieved 2009-06-06.

- ^ a b ASTM A325M - 09, retrieved 2009-06-13.

- ^ a b ASTM A490M - 09, 2009, retrieved 2009-06-06.

| Copper Tubing Sizes (CTS) for Plumbing | ||||

|---|---|---|---|---|

| Nominal size |

Outside diameter (OD) [in (mm)] |

Inside diameter (ID) [in (mm)] | ||

| Type K | Type L | Type M | ||

| 3/8 | 1⁄2 (12.700) | 0.402 (10.211) | 0.430 (10.922) | 0.450 (11.430) |

| 1/2 | 5⁄8 (15.875) | 0.528 (13.411) | 0.545 (13.843) | 0.569 (14.453) |

| 5/8 | 3⁄4 (19.050) | 0.652 (16.561) | 0.668 (16.967) | 0.690 (17.526) |

| 3/4 | 7⁄8 (22.225) | 0.745 (18.923) | 0.785 (19.939) | 0.811 (20.599) |

| 1 | 1+1⁄8 (28.575) | 0.995 (25.273) | 1.025 (26.035) | 1.055 (26.797) |

| 1-¼ | 1+3⁄8 (34.925) | 1.245 (31.623) | 1.265 (32.131) | 1.291 (32.791) |

| 1-½ | 1+5⁄8 (41.275) | 1.481 (37.617) | 1.505 (38.227) | 1.527 (38.786) |

| 2 | 2+1⁄8 (53.975) | 1.959 (49.759) | 1.985 (50.419) | 2.009 (51.029) |

| 2-½ | 2+5⁄8 (66.675) | 2.435 (61.849) | 2.465 (62.611) | 2.495 (63.373) |

| 3 | 3+1⁄8 (79.375) | 2.907 (73.838) | 2.945 (74.803) | 2.981 (75.717) |

| Unified Screw Threads - UNC, UNF and UNEF [1] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Major diameter in (mm) |

Threads per inch and Pitch | Tap drill size - Preferred sizes[2] | |||||||

| Coarse (UNC) |

Fine (UNF) |

Extra fine (UNEF) |

Coarse | Fine | Extra fine | ||||

| TPI | Pitch [in (mm)] |

TPI | Pitch [in (mm)] |

TPI | Pitch [in (mm)] | ||||

| #0 = 0.0600 (1.5240) | X | – | 80 | 0.012500 (0.3175) | X | – | 3⁄64 in | ||

| #1 = 0.0730 (1.8542) | 64 | 0.015625 (0.3969) | 72 | 0.013888 (0.3528) | X | – | #53 | #53 | |

| #2 = 0.0860 (2.1844) | 56 | 0.017857 (0.4536) | 64 | 0.015625 (0.3969) | X | – | #50 | #50 | |

| #3 = 0.0990 (2.5146) | 48 | 0.020833 (0.5292) | 56 | 0.017857 (0.4536) | X | – | #47 | #45 | |

| #4 = 0.1120 (2.8448) | 40 | 0.025000 (0.6350) | 48 | 0.020833 (0.5292) | X | – | #43 | #42 | |

| #5 = 0.1250 (3.1750) | 40 | 0.025000 (0.6350) | 44 | 0.022727 (0.5773) | X | – | #38 | #37 | |

| #6 = 0.1380 (3.5052) | 32 | 0.031250 (0.7938) | 40 | 0.025000 (0.6350) | X | – | #36 | #33 | |

| #8 = 0.1640 (4.1656) | 32 | 0.031250 (0.7938) | 36 | 0.027778 (0.7056) | X | – | #29 | #29 | |

| #10 = 0.1900 (4.8260) | 24 | 0.041667 (1.0583) | 32 | 0.031250 (0.7938) | X | – | #25 | #21 | |

| #12 = 0.2160 (5.4864) | 24 | 0.041667 (1.0583) | 28 | 0.035714 (0.9071) | 32 | 0.031250 (0.7938) | #16 | #14 | |

| 1⁄4 = 0.2500 (6.3500) | 20 | 0.050000 (1.2700) | 28 | 0.035714 (0.9071) | 32 | 0.031250 (0.7938) | #7 | #3 | |

| 5⁄16 = 0.3125 (7.9375) | 18 | 0.055556 (1.4111) | 24 | 0.041667 (1.0583) | 32 | 0.031250 (0.7938) | F | I | |

| 3⁄8 = 0.3750 (9.5250) | 16 | 0.062500 (1.5875) | 24 | 0.041667 (1.0583) | 32 | 0.031250 (0.7938) | 5⁄16 | Q | |

| 7⁄16 = 0.4375 (11.1125) | 14 | 0.071428 (1.8143) | 20 | 0.050000 (1.2700) | 28 | 0.035714 (0.9071) | U | 25⁄64 in | |

| 1⁄2 = 0.5000 (12.7000) | 13 | 0.076923 (1.9538) | 20 | 0.050000 (1.2700) | 28 | 0.035714 (0.9071) | 27⁄64 in | 29⁄64 in | |

| 9⁄16 = 0.5625 (14.2875) | 12 | 0.083333 (2.1167) | 18 | 0.055556 (1.4111) | 24 | 0.041667 (1.0583) | 31⁄64 in | 33⁄64 in | |

| 5⁄8 = 0.6250 (15.8750) | 11 | 0.090909 (2.3091) | 18 | 0.055556 (1.4111) | 24 | 0.041667 (1.0583) | 17⁄32 in | 37⁄64 in | |

| 3⁄4 = 0.7500 (19.0500) | 10 | 0.100000 (2.5400) | 16 | 0.062500 (1.5875) | 20 | 0.050000 (1.2700) | 21⁄32 in | 11⁄16 in | |

| 7⁄8 = 0.8750 (22.2250) | 9 | 0.111111 (2.8222) | 14 | 0.071428 (1.8143) | 20 | 0.050000 (1.2700) | 49⁄64 in | 13⁄16 in | |

| 1 = 1.0000 (25.4000) | 8 | 0.125000 (3.1750) | 12 | 0.083333 (2.1167) | 20 | 0.050000 (1.2700) | 7⁄8 in | 59⁄64 in | |

Experiments

[edit]| Unified Screw Threads - UNC, UNF and UNEF [3] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Major diameter in (mm) |

Threads per inch and Pitch | Tap drill size - Preferred sizes[4] | |||||||

| Coarse (UNC) |

Fine (UNF) |

Extra fine (UNEF) |

Coarse | Fine | Extra fine | ||||

| TPI | Pitch [in (mm)] |

TPI | Pitch [in (mm)] |

TPI | Pitch [in (mm)] | ||||

| #0 = 0.0600 (1.5240) | X | – | 80 | 0.012500 (0.3175) | X | – | 3/64 in | ||

- ^ Oberg, Erik (1975). Machinery's Handbook (Twentieth ed.). New York: Industrial Press, Inc. pp. 1296–1304.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ For a metric conversion see the drill bit sizes article.

- ^ Oberg, Erik (1975). Machinery's Handbook (Twentieth ed.). New York: Industrial Press, Inc. pp. 1296–1304.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ For a metric conversion see the drill bit sizes article.

|

|

|

|

|

|

|label42 = Mass |data42 =

|label43 = Axle load |data43 =

|label44 = Acceleration |data44 =

|label45 = Deceleration |data45 =

|label46 = Traction system |data46 =

|label47 = Engine(s) |data47 =

|label48 = Power output |data48 =

|label49 = Transmission |data49 =

|label50 = Auxiliaries |data50 =

|label51 = Power supply |data51 =

|label52 = Train heating |data52 =

|label53 = Electric system(s) |data53 =

|label54 = Current collection method |data54 =

|label55 = UIC classification |data55 =

|label56 = AAR wheel arrangement |data56 =

|label57 = Bogies |data57 =

|label58 = Braking system(s) |data58 =

|label59 = Safety system(s) |data59 =

|label60 = Coupling system |data60 =

|label61 = Multiple working |data61 =

|label70 = Gauge |data70 =

| Gauge | Nominal [in (mm)] |

Max [in (mm)] |

Min [in (mm)] |

|---|---|---|---|

| 10 | 0.1345 (3.42) | 0.1405 (3.57) | 0.1285 (3.26) |

| 11 | 0.1196 (3.04) | 0.1256 (3.19) | 0.1136 (2.89) |

| 12 | 0.1046 (2.66) | 0.1106 (2.81) | 0.0986 (2.50) |

| 14 | 0.0747 (1.90) | 0.0797 (2.02) | 0.0697 (1.77) |

| 16 | 0.0598 (1.52) | 0.0648 (1.65) | 0.0548 (1.39) |

| 18 | 0.0478 (1.21) | 0.0518 (1.32) | 0.0438 (1.11) |

| 20 | 0.0359 (0.91) | 0.0389 (0.99) | 0.0329 (0.84) |

| 22 | 0.0299 (0.76) | 0.0329 (0.84) | 0.0269 (0.68) |

| 24 | 0.0239 (0.61) | 0.0269 (0.68) | 0.0209 (0.53) |

| 26 | 0.0179 (0.45) | 0.0199 (0.51) | 0.0159 (0.40) |

| 28 | 0.0149 (0.38) | 0.0169 (0.43) | 0.0129 (0.33) |

| Thickness [in (mm)] |

Sheet width | |

|---|---|---|

| 36 (914.4) [in (mm)] |

48 (1,219) [in (mm)] | |

| 0.018–0.028 (0.46–0.71) | 0.002 (0.051) | 0.0025 (0.064) |

| 0.029–0.036 (0.74–0.91) | 0.002 (0.051) | 0.0025 (0.064) |

| 0.037–0.045 (0.94–1.14) | 0.0025 (0.064) | 0.003 (0.076) |

| 0.046–0.068 (1.2–1.7) | 0.003 (0.076) | 0.004 (0.10) |

| 0.069–0.076 (1.8–1.9) | 0.003 (0.076) | 0.004 (0.10) |

| 0.077–0.096 (2.0–2.4) | 0.0035 (0.089) | 0.004 (0.10) |

| 0.097–0.108 (2.5–2.7) | 0.004 (0.10) | 0.005 (0.13) |

| 0.109–0.125 (2.8–3.2) | 0.0045 (0.11) | 0.005 (0.13) |

| 0.126–0.140 (3.2–3.6) | 0.0045 (0.11) | 0.005 (0.13) |

| 0.141–0.172 (3.6–4.4) | 0.006 (0.15) | 0.008 (0.20) |

| 0.173–0.203 (4.4–5.2) | 0.007 (0.18) | 0.010 (0.25) |

| 0.204–0.249 (5.2–6.3) | 0.009 (0.23) | 0.011 (0.28) |

| Thickness [in (mm)] |

Sheet width | |

|---|---|---|

| 36 (914.4) [in (mm)] |

48 (1,219) [in (mm)] | |

| 0.017–0.030 (0.43–0.76) | 0.0015 (0.038) | 0.002 (0.051) |

| 0.031–0.041 (0.79–1.04) | 0.002 (0.051) | 0.003 (0.076) |

| 0.042–0.059 (1.1–1.5) | 0.003 (0.076) | 0.004 (0.10) |

| 0.060–0.073 (1.5–1.9) | 0.003 (0.076) | 0.0045 (0.11) |

| 0.074–0.084 (1.9–2.1) | 0.004 (0.10) | 0.0055 (0.14) |

| 0.085–0.099 (2.2–2.5) | 0.004 (0.10) | 0.006 (0.15) |

| 0.100–0.115 (2.5–2.9) | 0.005 (0.13) | 0.007 (0.18) |

| 0.116–0.131 (2.9–3.3) | 0.005 (0.13) | 0.0075 (0.19) |

| 0.132–0.146 (3.4–3.7) | 0.006 (0.15) | 0.009 (0.23) |

| 0.147–0.187 (3.7–4.7) | 0.007 (0.18) | 0.0105 (0.27) |

References

[edit]- ^ "ASTM-AISI Thickness Tolerance Ranges" (PDF). CoyoteSteel.com. Retrieved 20 June 2013.

{{cite web}}: Check date values in:|date=(help) - ^ a b c "Sheet metal material". Retrieved 2009-07-26.

Tryal

[edit]Obsolete metric threads, DIN13

[edit]| Nominal diameter D (mm) |

Pitch P (mm) "coarse" |

Pitch P (mm) "fine" |

|---|---|---|

| 5.5 | 0.9 | 0.5 |