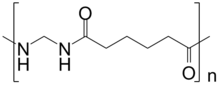

Nylon 1,6

Nylon 1,6 (aka polyamide 1,6) is a type of polyamide or nylon.[1] Unlike most other nylons, nylon 1,6 is not a condensation polymer, but instead is formed by an acid-catalyzed synthesis from adiponitrile, formaldehyde, and water. The material was produced and studied by researchers at DuPont in the 1950s.[2] Synthesis can be performed at room temperature in open beakers.

Synthesis of nylon 1,6

[edit]Nylon 1,6 is synthesized from adiponitrile, formaldehyde, and water by acid catalysis. Adiponitrile and formaldehyde (aqueous, paraformaldehyde, or trioxane) are combined with an acid (typically sulfuric acid) in a reactor. The reaction can be performed at room temperature. However, the reaction is exothermic, and especially at high ratios of formaldehyde to adiponitrile, cooling may be required.

CH2O + NC-(CH2)4-CN + H2O → [-NH-CH2-NH-OC-(CH2)4-CO-]n

Addition of water to the reaction mixture readily precipitates the nylon 1,6 product, which can then be isolated and washed with water to afford high purity polymer.

Properties and applications

[edit]The DuPont evaluations of the 1950s era indicated that polyamide-1,6 was less acid stable than nylon 66, and melts over 300–325 °C, with some decomposition. However, films were reported to have been successfully pressed at 275–290 °C. Molecular weight determined to be ~22,000–34,000 via an osmotic pressure method.[3] The polymer was believed to be significantly branched and cross-linked owing to side reactions occurring during the acid catalyzed polymerization, but this was not conclusively established.

Similar to other formaldehyde-based thermoset resins, thermal behavior of the polymer is a function of the CH2O/ADN ratio employed in the synthesis.[4][5]

Melting point was found to increase with increasing synthesis CH2O/ADN ratio, along with apparent increase in cross-linking, and reduction in crystallinity. Additionally, spectral features of 1H-NMR of nylon 1,6 samples were found to trend with CH2O/ADN synthesis ratio as well. Collectively, these properties parallel those of other formaldehyde-based thermoset resins, and it is interesting that nylon 1,6 is a rare example of a polyamide thermoset resin rather than a thermoplastic material.

Nylon 1,6 has been reported to exhibit a high moisture absorbance owing to the significant density of amide residues in the polymer, >130% of its weight (compare to ~2–2.5% for nylon 66 and nylon 6).

References

[edit]- ^ Palmer, Robert J. (2002-01-01). "Polyamides, Plastics". Encyclopedia of Polymer Science and Technology. John Wiley & Sons, Inc. doi:10.1002/0471440264.pst251. ISBN 9780471440260.

- ^ Magat, Eugene E.; Faris, Burt F.; Reith, John E.; Salisbury, L. Frank (1951-03-01). "Acid-catalyzed Reactions of Nitriles. I. The Reaction of Nitriles with Formaldehyde1". Journal of the American Chemical Society. 73 (3): 1028–1031. doi:10.1021/ja01147a042. ISSN 0002-7863.

- ^ Magat, Eugene E.; Chandler, Leonard B.; Faris, Burt F.; Reith, John E.; Salisbury, L. Frank (1951-03-01). "Acid-catalyzed Reactions of Nitriles. II. Polyamides from Formaldehyde and Dinitriles". Journal of the American Chemical Society. 73 (3): 1031–1035. doi:10.1021/ja01147a043. ISSN 0002-7863.

- ^ Que, Zeli; Furuno, Takeshi; Katoh, Sadanobu; Nishino, Yoshihiko (2007-03-01). "Effects of urea–formaldehyde resin mole ratio on the properties of particleboard". Building and Environment. 42 (3): 1257–1263. doi:10.1016/j.buildenv.2005.11.028.

- ^ Lenghaus, K; Qiao, G. G; Solomon, D. H (2001-04-01). "The effect of formaldehyde to phenol ratio on the curing and carbonisation behaviour of resole resins". Polymer. 42 (8): 3355–3362. doi:10.1016/S0032-3861(00)00710-2.