Freedom and constraint topologies

Freedom and constraint topologies (a.k.a., freedom, actuation, and constraint topologies; or simply FACT).[1][2][3] is a mechanical design framework developed by Dr. Jonathan B. Hopkins. The framework offers a library of vector spaces with visual representations to guide the analysis and synthesis of flexible systems. Flexible systems are devices, mechanisms, or structures that deform to achieve desired motion such as compliant mechanisms, flexures, soft robots, and mechanical metamaterials.

History

[edit]The FACT design approach was created in 2005 by Jonathan Brigham Hopkins while a Master’s student in Professor Martin L. Culpepper’s Precision Compliant Systems Laboratory at MIT. FACT was first published in a short conference paper in the 2006 proceedings of the 21st Annual Meeting of the American Society for Precision Engineering[4] and was later published in depth in Hopkins’ 2007 Master's thesis.[5] FACT has been expanded in later works such as Hopkins' 2010 PhD Thesis.

Alternatives

[edit]Other compliant mechanism design methods include generative design, pseudo-rigid-body analysis,[6] and other constraint-based and [screw theory]-based design approaches.[7] See the main article for pros and cons of kinematics and structural optimization.

Fundamentals

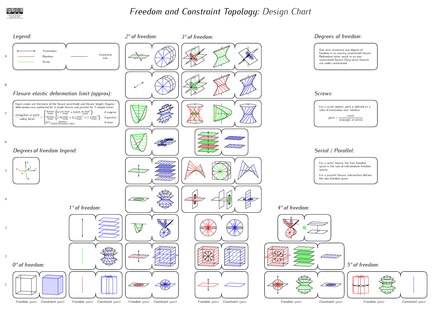

[edit]FACT combines principles of screw theory, linear algebra, projective geometry, and exact-constraint design. The methodology employs a library of vector spaces derived from these principles and represented by geometric shapes. These shapes are categorized into freedom spaces, constraint spaces, and actuation spaces, each serving a unique purpose in the design process.

- Freedom Spaces represent the allowed deformations of a system; the system's degrees of freedom (DOF). They are modeled as twist vectors.

- Constraint Spaces guide the arrangement of flexible elements within a system to ensure it deforms only as intended. Each constraint space is complementary to a freedom space. They are modeled as wrench vectors.

- Actuation Spaces guide the arrangement, number, and kind of actuators within a flexible system so that the system deforms as desired under load. Like constraint spaces, they are modeled as wrench vectors[8]

FACT synthesis

[edit]The FACT library allows traversal of the complete solution space of flexible systems for any combination of degrees of freedom. The rules of FACT vary depending on the configuration of the flexible system desired. Here are the basic steps to design a parallel flexure bearing.

- Determine how the stage should move. What degrees of freedom (DOF) are needed? (Fig 1)

- Find the matching freedom space in the FACT library (Fig 2)

- Identify the constraint space matching the required freedom space (Fig 2)

- Select and arrange flexible elements that satisfy the constraint space. According to Maxwell, the degrees of constraint and degrees of freedom must sum to 6 for the system to be exactly constrained[9] (Fig 3)

- Design the rigid bodies and connect each flexture to each body at their ends. When one body is held fixed, it becomes the "ground". The other body (the "stage") then attains the chosen DOF.

Sometimes it may be desireable to over-constrain the system by adding redundant constraints within the constraint space. This adds stiffness and may be required for symmetry, which can improve thermal stability.

Limitations

[edit]All flexible systems can be organized according to three primary configurations – parallel, serial, and hybrid. FACT alone covers parallel, serial, and some hybrid systems.

- Parallel systems [1][2][3] consist of two rigid bodies connected directly together by parallel flexible elements.

- Serial systems [10][11] consist of two or more parallel systems stacked or nested in a chain from one rigid body to the next.

- Hybrid systems[12] consist of any other configuration of parallel and serial system combinations.

- Interconnected hybrid systems[13] are a special kind of hybrid configuration where intermediate rigid bodies are also interconnected together by flexible elements, which create internal loops within the system. FACT must be supplemented with Graph theory in order to handle such systems.[13] Mechanical metamaterials fall in this category.[14]

Further Learning

[edit]FACT is covered in various educational resources:

- It is taught in a graduate class at UCLA by Dr. Hopkins.[15]

- The course is available on YouTube via the channel "The FACTs of Mechanical Design" as a free lecture series.[16]

- The book "Handbook of Compliant Mechanisms" discusses FACT within the context of compliant mechanism design.[17]

See Also

[edit]- Mechanism (engineering)

- Degrees of freedom

- Six degrees of freedom

- Compliant mechanism

- Engineering analysis

- Engineering design

- Kinematics

- General topology

- Axiomatic design

- Overconstrained mechanism

References

[edit]- ^ a b Hopkins, Jonathan (2010). "Synthesis of Multi-degree of Freedom, Parallel Flexure System Concepts via Freedom and Constraint Topology (FACT)—Part I: Principles". Precision Engineering. 34 (2): 259-270. doi:10.1016/j.precisioneng.2009.06.008.

- ^ a b Hopkins, Jonathan (2010). "Synthesis of Multi-degree of Freedom, Parallel Flexure System Concepts via Freedom and Constraint Topology (FACT)—Part II: Practice". Precision Engineering. 34 (2): 271-278. doi:10.1016/j.precisioneng.2009.06.007.

- ^ a b Howell, Larry (4 February 2013). Handbook of Compliant Mechanisms. Oxford, UK: John Wiley and Sons Ltd. p. 79-92. ISBN 9781119953456.

- ^ Hopkins, Jonathan. "A Quantitative, Constraint-based Design Method for Multi-axis Flexure Stages for Precision Positioning and Equipment, Proc. of the 21st Annual Meeting of the American Society for Precision Engineering (ASPE), Monterey, CA, October 2006". CiteSeerX 10.1.1.568.6427.

- ^ Hopkins, Jonathan. "Design of Parallel Flexure Systems via Freedom and Constraint Topologies (FACT), M.S. thesis, Massachusetts Institute of Technology". MIT Libraries. hdl:1721.1/39879.

- ^ Jensen, Brian D.; Howell, Larry L. (1 December 2003). "Identification of Compliant Pseudo-Rigid-Body Four-Link Mechanism Configurations Resulting in Bistable Behavior". Journal of Mechanical Design. 125 (4): 701–708. doi:10.1115/1.1625399.

- ^ Li, Chenglin; Chen, Shih-Chi (1 May 2023). "Design of compliant mechanisms based on compliant building elements. Part I: Principles". Precision Engineering. 81: 207–220. doi:10.1016/j.precisioneng.2023.01.006.

- ^ Hopkins, Jonathan (2010). "A Screw Theory Basis for Quantitative and Graphical Design Tools that Define Layout of Actuators to Minimize Parasitic Errors in Parallel Flexure Systems". Precision Engineering. 34 (4): 767-776. doi:10.1016/j.precisioneng.2010.05.004.

- ^ Maxwell, James Clerk; Nivens, W. D. (1890). General Considerations Concerning Scientific Apparatus in The Scientific Papers of James Clerk Maxwell. Dover Press.

- ^ Hopkins, Jonathan. "Design of flexure-based motion stages for mechatronic systems via Freedom, Actuation and Constraint Topologies (FACT), Ph.D. thesis, Massachusetts Institute of Technology". MIT Libraries. hdl:1721.1/62511.

- ^ Hopkins, Jonathan (October 2011). "Synthesis of Precision Serial Flexure Systems Using Freedom and Constraint Topologies (FACT)". Precision Engineering. 35 (4): 638-649. doi:10.1016/j.precisioneng.2011.04.006.

- ^ Hopkins, Jonathan (October 1, 2013). "Designing Hybrid Flexure Systems and Elements Using Freedom and Constraint Topologies". Mechanical Sciences. 4 (2): 319-331. Bibcode:2013MecSc...4..319H. doi:10.5194/ms-4-319-2013.

- ^ a b Sun, Frederick (June 2017). "Mobility and Constraint Analysis of Interconnected Hybrid Flexure Systems via Screw Algebra and Graph Theory". Journal of Mechanisms and Robotics. 9 (3): 031018. doi:10.1115/1.4035993.

- ^ Shaw, Lucas (January 2019). "Computationally Efficient Design of Directionally Compliant Metamaterials". Nature Communications. 10 (1): 291. Bibcode:2019NatCo..10..291S. doi:10.1038/s41467-018-08049-1. PMC 6336888. PMID 30655524.

- ^ "Flexible Research Group". UCLA. University of California, Los Angeles.

- ^ "The FACTs of Mechanical Design". YouTube.

- ^ Howell, Larry (2013). Handbook of Compliant Mechanisms. John Wiley & Sons. ISBN 978-1-119-95345-6.